Introducing the Production Refine Behind a Silicone Rubber Keypad and Its Applications

Introducing the Production Refine Behind a Silicone Rubber Keypad and Its Applications

Blog Article

Recognizing the Conveniences of Using Silicone Rubber Keypads in Modern Electronics

The usage of silicone rubber keypads in contemporary electronic devices provides a compelling instance for their adoption throughout various sectors. The discussion does not finish there, as further expedition reveals added elements that can influence the choice to utilize silicone rubber keypads in item layout.

Durability and Durability

The sturdiness of silicone rubber keypads is a defining quality that boosts their charm in modern-day electronic devices. These keypads are engineered to stand up to comprehensive wear and tear, making them a suitable choice for gadgets requiring regular usage. The inherent versatility of silicone enables an extensive life expectancy, as the product can endure repeated compression and deformation without shedding its initial form or functionality.

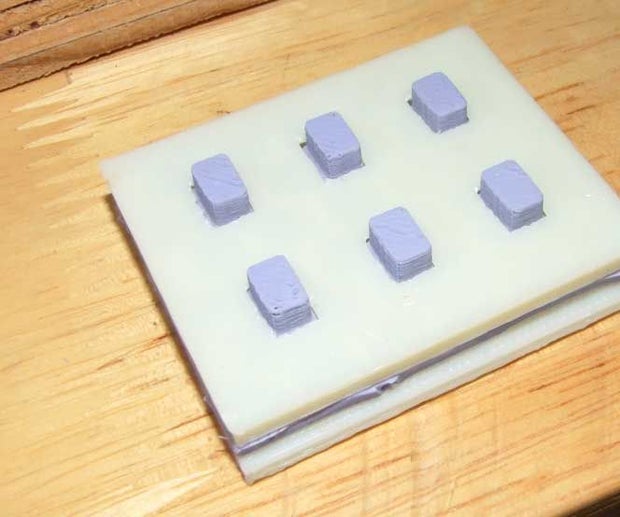

In addition, the production process of silicone keypads enables precise modification, making it possible for the style of complex forms and tactile feedback attributes that improve user experience. Consequently, makers can create durable keypads tailored to details applications, enhancing their dependability and performance in different electronic devices. Inevitably, the longevity and durability of silicone rubber keypads position them as a preferred selection in the landscape of modern-day electronics.

Resistance to Environmental Factors

Silicone rubber keypads are not only recognized for their toughness and longevity yet likewise for their impressive resistance to environmental factors. This material shows extraordinary performance in a range of challenging conditions, consisting of exposure to severe temperatures, wetness, and UV radiation. Silicone Rubber Keypad. Silicone rubber keeps its structural honesty and functionality across a vast temperature level variety, from -60 ° C to 250 ° C, making it ideal for both exterior and indoor applications

In addition, silicone is inherently resistant to water and moisture, preventing damage from spills or condensation, which is vital for devices made use of in damp atmospheres. Its hydrophobic homes make certain that moisture does not compromise the operational efficiency of the keypad.

In addition, silicone rubber's resistance to UV radiation protects the keypad from fading and degradation when subjected to sunlight for prolonged periods. This particular is specifically beneficial for customer electronics, automotive controls, and industrial devices, where extended exposure to the aspects is typical.

Modification and Style Adaptability

With a vast selection of customization options available, silicone rubber keypads can be tailored to meet specific design needs and visual choices. Suppliers can create keypads in various shapes, dimensions, and shades, permitting seamless combination right into diverse digital gadgets. This flexibility implies that designers can pick from an extensive their explanation combination of shades and structures, guaranteeing that the keypad matches the overall product layout while keeping brand identity.

Additionally, silicone rubber keypads can be built to consist of distinct attributes such as increased or recessed buttons, varying responsive comments, and even backlighting alternatives. This versatility not only boosts the aesthetic appeal but additionally enables for practical differentiation in item offerings.

Inevitably, the personalization and design versatility inherent in silicone rubber keypads make them an excellent option for modern-day electronics, permitting the development of straightforward, cosmetically pleasing, and useful user interfaces customized to certain market needs.

Boosted User Experience

Enhancing individual experience via intuitive style is an essential benefit of silicone rubber keypads. These keypads are engineered to supply responsive feedback, allowing individuals to obtain prompt sensory confirmation upon pressing a switch. This responses is essential for making certain precision in device procedure, which boosts total user fulfillment.

The ergonomic layout of silicone rubber keypads further adds to an enhanced individual experience. They are usually shaped to fit the contours of the fingers, making them comfortable to use over prolonged durations - Silicone Rubber Keypad. This is particularly beneficial in applications where frequent communication is needed, such as in clinical tools or customer electronic devices

In addition, silicone rubber keypads can be made with differing appearances and surface area coatings, accommodating diverse customer choices and boosting use. Their capacity to integrate backlighting and custom-made icons likewise permits much better exposure in low-light conditions, improving accessibility for all individuals.

Additionally, the longevity of silicone rubber makes certain that keypads keep their capability and appearance in time, reducing the need for substitute. This durability promotes a reputable user experience, as customers can rely on that their devices will perform continually throughout their life-span.

Cost-Effectiveness and Effectiveness

A significant advantage of silicone rubber keypads lies in their cost-effectiveness and performance in production. The manufacturing procedure of these keypads normally entails shot molding, which permits for high-volume manufacturing at relatively low prices.

Furthermore, silicone rubber keypads are sturdy and resistant to use, which better enhances their cost-effectiveness gradually. Their longevity decreases the demand for constant replacements, bring about lower general lifecycle prices for consumers and services alike.

Furthermore, these keypads can be tailored easily to satisfy details design requirements, which includes in their performance in terms of advancement time and sources. Quick prototyping capabilities Source enable business to bring their items to market extra quickly, offering a competitive side in the busy electronic devices landscape.

Verdict

In conclusion, silicone rubber keypads present various advantages that make them a recommended selection in contemporary electronics. Inevitably, silicone rubber keypads stand for a useful and efficient service for manufacturers intending to satisfy the needs of more modern consumer electronic devices.

The usage of silicone rubber keypads in modern electronic devices provides a compelling instance for their adoption throughout different industries.The longevity of silicone rubber keypads is a specifying characteristic that boosts their charm in modern-day electronics. Inevitably, the sturdiness and long life of silicone rubber keypads place them as a favored choice in the landscape of modern-day electronics.

In verdict, silicone rubber keypads present countless advantages that make them a recommended choice in modern-day electronics. Eventually, silicone rubber keypads stand for a efficient and functional solution for makers intending to meet the needs of modern consumer electronic devices.

Report this page